行业资讯

数控车床送料机械手常见问题及解决方法

对于数控车床送料机械手的常见故障要针对其具体的原因进行检修,常见故障有以下几个方面:

For the common faults of CNC lathe feeding manipulator, it should be overhauled for its specific reasons.

1.减速器声音不正常。通常是由于齿轮啮合不好、齿轮或轴承磨损严重或断齿、齿面有粘附物、箱体内有杂物或者轴承游隙太大导致的,需要检查和清理齿轮、齿面及轴承等。

The sound of the 1. reducer is abnormal. Usually due to poor gear meshing, gear or bearing wear serious or broken teeth, tooth surface adhesion, in the box, or bearing clearance too large, the need to check and clean gear, tooth surface and bearings.

2.减速器温度过高。可能是润滑油不干净或者质量不合格、注油太多或者散热条件不好导致的,按要求注入润滑油,清除减速器箱上的浮煤及杂物即可解决;链轮轴组温度过高。可能是轴承损坏或者润滑油不足导致的,需要更换轴承或者给足润滑油。

The temperature of the 2. reducer is too high. It may be that the lubricating oil is not clean or the quality is not qualified, the injection is too much or the heat dissipation is not good. It can be injected into the lubricating oil as required to remove the floating coal and sundries on the reducer box; the sprocket shaft group is too high in temperature. It may be caused by damage to the bearing or lack of lubricating oil. It is necessary to replace the bearing or give enough lubricant.

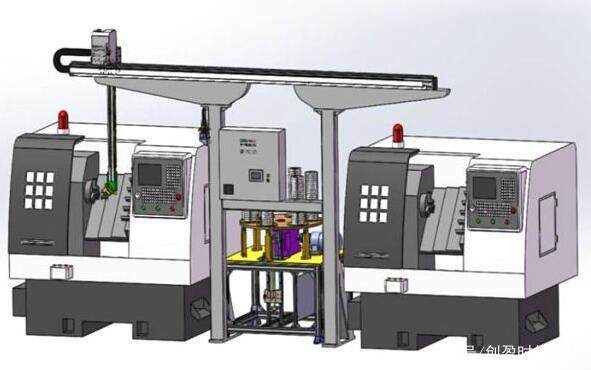

数控机床机械手

数控机床机械手3.刮板链跳链或掉链。可能是由于链条卡进金属物或者刮板链太松导致的,需要对金属物进行清理或者紧链;电动机无法启动或者启动后缓缓停转。可能是供电电压太低、负荷太大或者接触故障导致的,需要检查电压、负荷、控制电路等。

3. chain chain or chain drop chain. It may be caused by the chain card entering the metal or the scraper chain too loose. It is necessary to clean the metal or tighten the chain; the motor can not start or start to stop slowly. It may be the power supply voltage is too low, the load is too large or the contact fault is caused. It is necessary to check the voltage, load, control circuit and so on.

4.电动机温升高。可能是由于电动机频繁启动、长时间超负荷运转、散热不良或缺相运行等造成的,应当检查电动机绝缘、实际电流、风扇等;减速器漏油。可能是密封圈损坏或者上下箱体合而不严,各箱盖压不紧导致的,需要更换损坏的密封圈,合紧上下箱体以及端盖螺栓。

4. the temperature of the motor rises. It may be due to the frequent start of motor, long time overload operation, bad heat dissipation or lack of phase operation. The insulation of motor, actual current, fan and so on should be checked, and the reducer is leaking. It is possible that the seal ring is damaged or the upper and lower box is closed and not strict, the pressure of each box is not tight, and the damaged seal ring should be replaced, the upper and lower box and the end cover bolt should be tightened.

在数控车床送料机械手的使用中还要检查数控车床送料机械手的速度以及数控车床送料机械手内的原料或者成品的厚度,以提高输送量。对于中间卸料的数控车床送料机械手要尽量加长中间卸料口的长度,延长可卸料时间,同时在链条上加装回料斗,防止出现积料,从而使数控车床送料机械手能够正常运行。

In the use of CNC lathe feeding manipulator, we should check the speed of the manipulator and the thickness of the raw material or finished product in the CNC lathe, so as to improve the delivery. The numerical control lathe for the intermediate unloading is to lengthen the length of the intermediate discharge port, prolong the discharging time, and add the hopper on the chain to prevent the appearance of the material, so that the manipulator of the CNC lathe is able to operate normally.

文章由:数控车床https://www.zhoushicnc.com/东莞市周氏数控设备有限公司整理提供,此文观点不代表本站观点

以上便是数控车床送料机械手常见问题及解决方法的介绍希望可以帮助到大家,更多的数控知识,请关注我们。

本文标题:数控车床送料机械手常见问题及解决方法 地址:[ https://www.zhoushicnc.com/xinwenzixun/xingyezixun/596.html ]

新闻资讯

- 数控车床加工双头螺栓10/15

- 数控车床哪个品牌好?性价比高03/24

- 适合数控机床加工的零件有哪些?02/05

- 车铣复合机床大概多少钱一台?01/09

联系我们

手机:13649862382

电话:13649862382

邮箱:226284020@qq.com

地址:东莞市大岭山镇颜屋村颜莲路86号鑫峰科技园C栋一楼

微信咨询:

226284020

226284020